Category : Best Innovation in SDG Inclusion

HONORABLE MENTION

Innovation Title : Akij Lacquer Grade Board

Organization : Akij Particle Board Mills Limited

Background

The furniture Sector is going to be the next big thing in our economy, as the trend suggests. Each year, we lose almost 7 million cubic meters of timber for the ever-increasing furniture and interior sector (Source: FAO, 2015). Bangladesh’s current volume of forest resources is approximately 17% of the total land area, which is distributed unevenly.

With the philosophy of Environmental Balance, Akij Group has launched their particle board unit to fulfill the ever-growing demand of the furniture and interior making industries. The company can cater to almost 5% of daily timber demand with 1029 cubic meter production capacity/ day. This gigantic production capacity of Akij Board puts us ahead in serving the need of wood-substituting with boards.

Objectives

■ To create a sustainable substitute for timber and to overcome the growing demands of our rural markets.

■ To develop a product that will save deforestation and protect the environment with an eco-friendly and sustainable production plant.

■ To innovate a product that will completely substitute solid timber by being designable, lacquerable, and as well as affordable.

The Idea

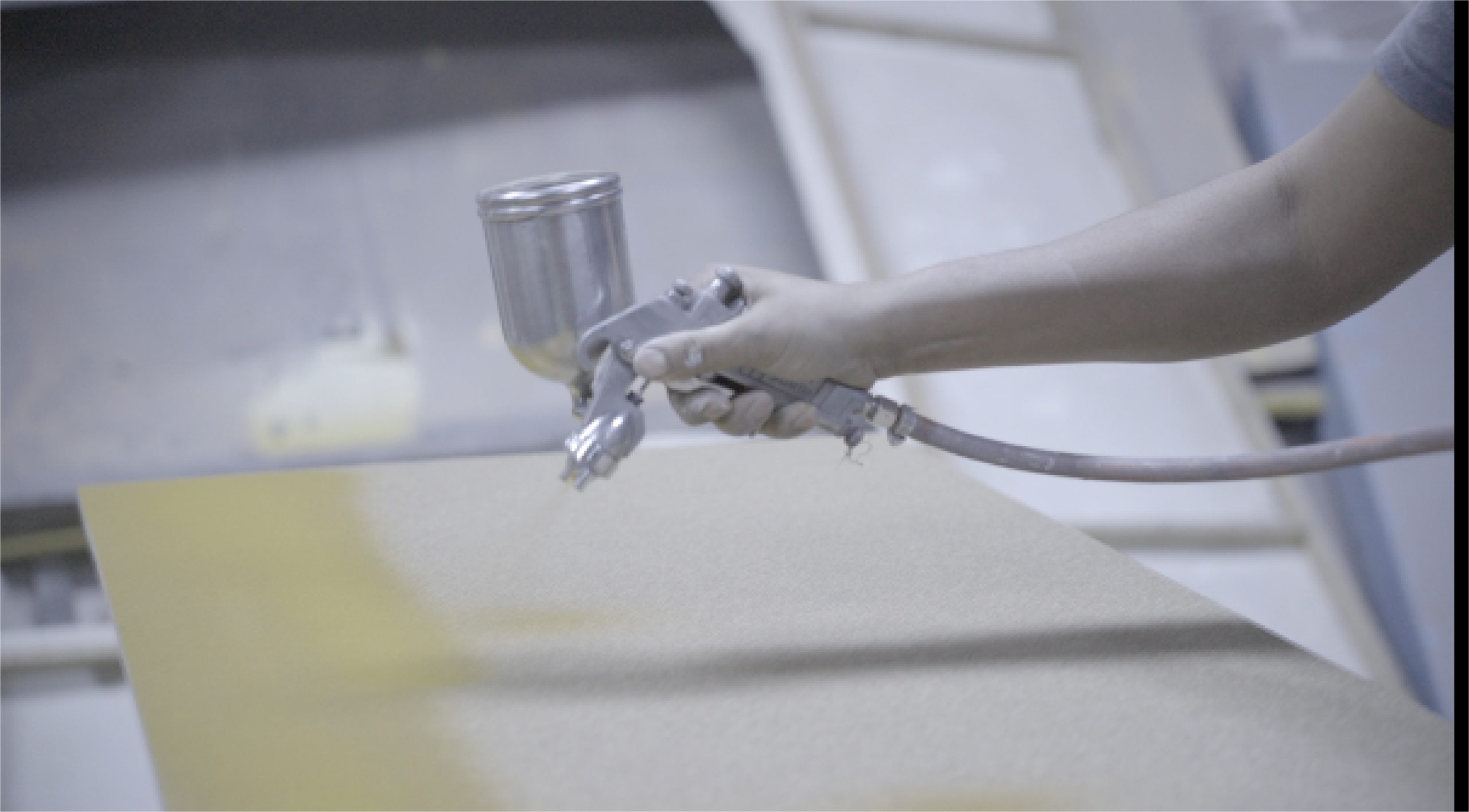

The idea behind the product is to provide a woodchips-based particle board solution that will cater to the need-gap of the furniture market. Akij Board Product Development team came up with a solution by innovating a new technology to produce boards made with wood chips from tree branches instead of logs. The products allow to engrave designs up to 4 mm that can be lacquered, sanding, filler materials, and surprisingly take less time & cost to achieve a smoother lacquered finish. Besides, establishing the core value, the product will be affordable and environmentally friendly as well. So, a new product came into the production named ‘Lacquer Grade Board’ in 2018.

Execution

The innovation came into reality through engineering efficacy and several trials. Akij Lacquer Grade Board hit the market in 2018 following several trials. The core recipe behind the product was adding on different eco-friendly complied resin and wax in the production process to facilitate easy lacquering, increase the depth of surface layer chips which ensures designing on the product up to 4 mm. In addition, the world-famous German technology of particle board production unit ‘Siempelkamp’ empowered the product quality and consistency at its best.

Value Addition

Economic Value Addition: By using this innovation, the manufacturers can now produce wood-finished, designed, lacquered furniture without using the timber at minimum time and price. As a result, the industry grew at a 15% rate/year, creating employment of 2.5 million people. Most of it, Akij Lacquer Grade Board has bridged an 80% market gap with proper solutions. It has a significant contribution of about 40% to an overall 15% board industry growth.

Result and Impact

The consequences of this new product were revolutionary. The entire rural furniture market started using the Akij Lacquer Grade Board from district to union level at large scales. In just 3.5 years,

■ On average, 0.3 million cubic meters of solid wood are saved every year. Deforestation saw a sharp dip. ■ 80% of rural manufacturers now have access to this board.

■ Akij Board fetched a volume growth/year of 40%.

■ Board industry is booming; this contributed about 40% to an overall 15% board industry growth.